compressed air tank testing|DOT Certified Hydrotesting Service : maker All air compressor tanks are tested by the manufacturer and are affixed with a stamped certification tag that includes the tank rating. Future certifications are dictated by the air receiver tank size. Here are some of the updates you'll start to see soon: A new look for an improved experience. An easy-to-use floating tool bar for quick access to features. A smart way to sort and categorize to keep your inbox organized. An optimized mobile experience supported on even more browsers. Find out more about your Bell email services.

{plog:ftitle_list}

Embora não tenha conseguido uma boa recepção dos críticos, o filme ainda assim foi capaz de gerar uma bilheteria de US$ 405 milhões a partir . Ver mais

What is the simplest way to test an air compressor tank? How frequently should this test be performed? From what I understand, the only .Department of Transportation (DOT) regulations require compressed air/gas cylinders be periodically tested and inspected internally and externally by a DOT certified testing agency.

When inspecting your air compressor tank, it’s essential to perform a hydrostatic test to ensure it’s safe to operate. This test involves filling the tank with water and pressurizing it to a level higher than its maximum working . All air compressor tanks are tested by the manufacturer and are affixed with a stamped certification tag that includes the tank rating. Future certifications are dictated by the air receiver tank size. A simple procedure to pressure test an air compressor tank before putting it into use using a pressure washer and pressure gauge.CYLINDER HYDROSTATIC TESTING. We perform visual inspection as well as government controlled (TC#047) and certified hydrostatic testing of cylinders of all sizes. We can also refill all SCUBA and SCBA cylinders with laboratory tested, .

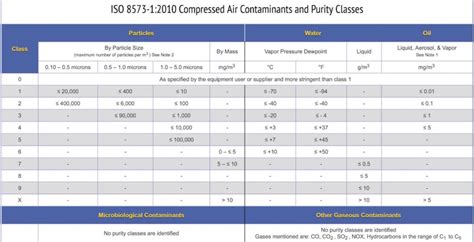

Your air receiver tank works hard to keep your compressed air system running at optimal efficiency. For best results and safe operation, it’s important to make sure you have adequate storage capacity for your . ISO 8573-1:2010 is an internationally accepted language that can be used between the compressor manufacturer, filter manufacturer, product manufacturer, and analytical laboratory to confirm the safety of compressed .Ninja Paintball is a certified DOT Hydrotesting facility (DOT ID #G777). We have over 10 years of experience in hydrostatic testing paintball tanks and cylinders for other industries.

Hydrostatic testing is a highly accurate method used to determine compliance with industry safety standards and is often employed to check that a recently repaired pressure system or .SAS is capable of testing all cylinders approved for use in the UK, including: Diving cylinders; BA cylinders; Paintball cylinders; Storage cylinders; Mixed gas cylinders; Airgun cylinders; Industrial cylinders; Specialist cylinders; We can test any cylinder between 0.1 litre and 256 litre, and can also collect and deliver them to you.TRI Air provides equipment to test compressed air samples as part of air quality compliance, safety, SQF. Medical. Solutions for medical gas testing standards including NFPA 99. Fire Service. Compressed breathing air quality for .

Using ISO 8573

The Department of Transportation (DOT) issues permits for different tanks, this determines the service life of a tank. There are many factors that go in to the special permits and with continued testing, permits can be renewed. .Auto service and support packages available! MES specializes in the hydro-testing and recertification of your SCBA and DOT storage cylinders. As the nation’s largest fire equipment distributor and servicing company, MES has 17 in-house service centers staffed with certified technicians trained to meet DOT requirements.

Periodic inspection and hydrostatic tank testing of compressed air tanks in accordance with the appropriate OSHA, FDNY, and DOT codes and regulations is essential to worker safety and health. FDNY Requirements For Hydrostatic Tank Testing: 1. Hydrostatic tank testing must be completed by a licensed certified tank tester with special equipment .

Hydrostatic Facility, at Safe Air Systems, is a state of the art testing facility with 4 computer operated test stands that have the capacity to test cylinders in large quantities. Our Hydrostatic Testing Systems are single pump units that have the capacity to test cylinders simultaneously at a rate of 7 cylinders per testing cycle.

The final technology you can employ is gas chromatography, a process often used in analytical chemistry to test the purity of a particular substance, such as compressed air in this case. This is the only method that can be used to ensure that you are in compliance with even the most stringent air quality requirements.

This section is not intended to apply to compressed air machinery and equipment used on transportation vehicles such as steam railroad cars, electric railway cars, and automotive equipment. 1910.169(a)(2) New and existing equipment. 1910.169(a)(2)(i) All new air receivers installed after the effective date of these regulations shall be . Employing a Standard for Compressed Air Testing Selecting ISO 8573-1 as the basis for compressed air quality monitoring and testing is the obvious choice, since it provides a common language that all involved parties can use. . type of system filtration for particle, water and oil removal; storage tank capacity; type of point-of-use filters .Discover everything you need to know about air compressor tanks. We provide a comprehensive guide on the best sizes for various uses, the different types available, safety precautions to take, and more. Stay informed with our professional, helpful insights and make the right decision for your air compressor needs.

Be provided with oxygen lines and fittings leading into external tanks. The lines shall be fitted with check valves to prevent reverse flow. . Additional fittings shall be provided so that test gauges may be attached whenever necessary. 1926.803(g)(1)(vi) . on every floor of every building not under compressed air, but used in connection .What is the average thickness of air compressor tanks? The average thickness of air compressor tanks can vary, but it typically ranges from 1/4 inch to 1/2 inch. Is a thicker tank always better for an air compressor? Not necessarily. The thickness of an air compressor tank depends on factors such as the size of the tank and the use of the . HPA Guns. High-pressure air paintball guns work with a separate compressed air tank to fire each shot. These tanks are typically made of either aluminum or carbon fiber, which offer different weight and durability characteristics.Compressed air tanks store air at high pressures, typically between 3,000 to 4,500 pounds per square inch (psi).

Any breathing air compliant compressor & filling station MUST undergo inspections, regular maintenance & have the following: a written scheme, quarterly air tests, a filling process, scuba cylinder testing (and stamps), air gun cylinder testing (and stamps). Air gun cylinder users: filling of your cylinders MUST be done at a facility like ours .This new paintball compressed air tank is ideal for any serious paintball player with a 68 cubic inch, 4500psi air bottle with a clean glossy gel-coat finish and a 5 year hydro test. Atop the new Valken Zero-G V2 paintball air tank is the new, .Refurbished - Valken Zero-G Riot 68/4500 Compressed Air Tank - Grey (031-0292) (Requires Hydro Testing) Customer Rating. Availability: Usually Ships in 24 to 48 Hours. Product Code: REFURB-TANK-VALKENZEROG68GREY1016. Was: 9.95 Sale Price .95. Preorder Item. I agree to the ANSgear.com Pre .

This review examines compressed air receiver tanks (CARTs) for the improved energy efficiency of various pneumatic systems such as compressed air systems (CAS), compressed air energy storage systems . Breathing Air Components. Quantifying the amount of oxygen present in a tank is a vital task of testing compressed breathing air. NFPA 1989 requires an oxygen level between 19.5 and 23.5 percent. The typical atmospheric level of oxygen at sea level is 20.9 percent, although the atmospheric oxygen level can vary based on factors such as elevation.%PDF-1.6 %âãÏÓ 17454 0 obj >stream hÞì›[¯$DZ ÿÊ~´ ¤‰[Þ€ :òƒ Ë„(? ‚0–F Š$x Ì ïìÚ½¾&gÆÃáåXÆQ¾ÄÄTDfu¯ŠªZ±;V-{²§Zþä6ö .

When inspecting your air compressor tank, it’s essential to perform a hydrostatic test to ensure it’s safe to operate. This test involves filling the tank with water and pressurizing it to a level higher than its maximum working pressure.TRI Air Testing can help with compressed air and pure gas testing for SCUBA Grade E, PADI dive air, oxygen compatible and more! TRI Air Testing compressed air and pure gas sampling equipment was designed to capture a non-pressurized sample of compressed breathing air for analysis by TRI Air Testing, an ISO 17025:2017 accredited laboratory.

A straightforward rule for sizing an air receiver tank for a reciprocating air compressor is to take the tool with the highest CFM requirement at the required PSI, multiply that CFM requirement by 1.25 or 1.5, then round up to the closest gallon size. Air Receiver Tank Size Per CFM Requirement.Piping distribution and air storage tanks, more prevalent in older systems, will have contaminants in the form of rust, pipe scale, mineral deposits and bacteria. . We can conduct periodic compressed air purity testing at the point of use with certified results that can be measured against ISO: 8573-1 standards, testing for particle content .

A compressed air test is a standardized procedure used to ascertain the quality of the produced air. Compressed air testing determines that the compressed air being supplied to industrial processes is free of impurities. . Nitrogen Generator for Marine Vessel Cargo Tank Inerting; GENERON’s Customized NOW Panel Nitrogen Generator: Provides .

Ninja Paintball Hydrotesting

Dunk and Bubble Leak Testing Systems. Dunk and bubble leak testing is a method of testing a part vessel or cavity for leaks by submerging it in a water tank. The part is filled with gas—typically compressed air—and leaks are identified by an operator monitoring whether a stream of air bubbles escapes from the part.

Are you wondering about compressed air tanks and how to determine if you require an air receiver tank? This comprehensive guide will provide you with detailed information about air receiver tanks, also known as storage tanks. Additionally, I'll elaborate on how these tanks work with compressed air and their role in optimizing efficiency within your . Compressed air testing is a standardized process of determining that the air being used in an industrial process is free of impurities. Typically, compressed air testing procedures involve three components: Water; Solid Particles; Oil; .

tear test method

tear test paper

tear test results

Hydro Testing

WEBTopper Bolo Palmeiras feitas especialmente para você. Mais de 68 produtos exclusivos. . Infantil Jogos e Brinquedos Jóias Lembrancinhas Móveis Papel e Cia Pets Religiosos Roupas . Topo de bolo / Topper de bolo Dia dos Pais Palmeira DIGITAL Mimos da Kauany R$ 15,00 3x R$ 5,42;

compressed air tank testing|DOT Certified Hydrotesting Service